-

-

First, click here to read safety information . This safety information may be updated at anytime so occasionally check for updates.

-

NOTE: This guide is intended to be followed online in order to fully utilize the links and documentation found within.

-

Open and inspect the contents of your SE300 whip kit to ensure you have all the parts listed on the BOM.

-

Included is a diagram of the whip wiring. Keep this handy, as we'll be referencing this throughout this guide.

-

-

-

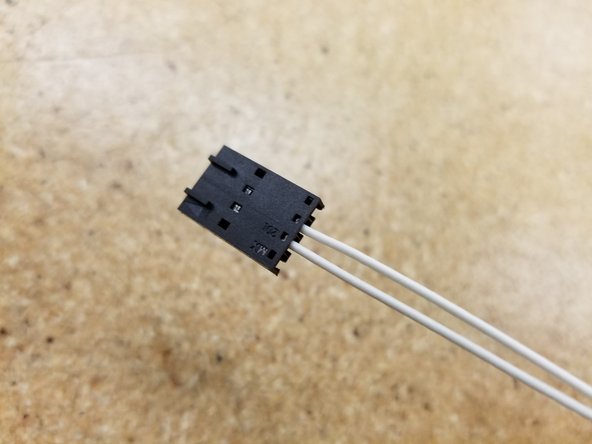

Begin inserting the wires into the black SL 10 position housing.

-

Be sure the small tab on the metal crimp terminal is facing the same direction as the square holes in the connector. If inserted properly, you should hear and feel a satisfying click as the tab seats. Give the wire a gently tug to make sure it's seated properly.

-

Repeat for the remainder of the wires, using the diagram from earlier as a guide.

-

-

-

Pass the wires through one of the shorter lengths of mesh loom material.

-

Tightly zip tie the bundle to hold everything in place.

-

Run everything through the wider cable boot, covering the zip tie and connector.

-

-

-

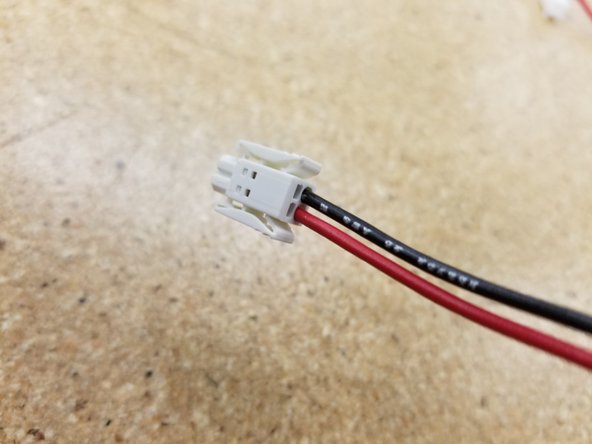

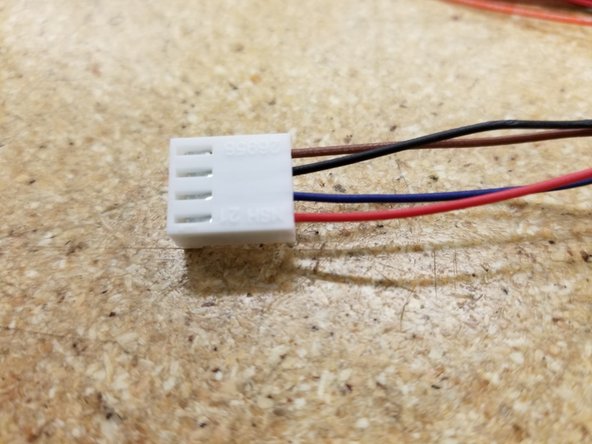

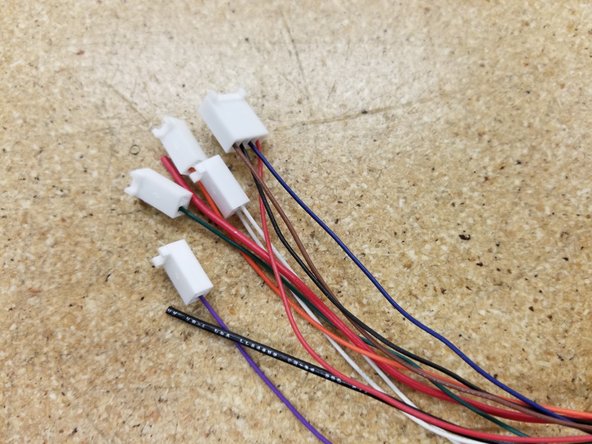

Insert the two white wires in the 4 pin SL connector just as you did for the 10 pin SL connector in Step 2.

-

Make sure an adequate amount of the PVC has been stripped from the red and black 20awg wire, and insert into the 2 pin push-in wire terminal as shown.

-

Remember to use the wire diagram from earlier as reference when needed

-

-

-

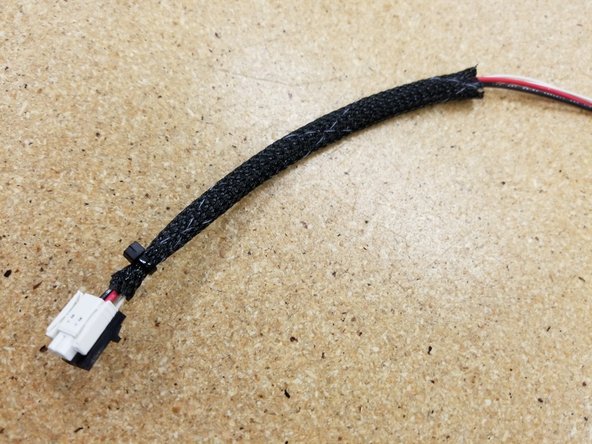

Pass the cables through the mesh loom, zip-tie them secure, and install the cable boot as we did in Step 3.

-

Zip tie the two cable bundles together at the top of the mesh looms as shown.

-

-

-

Pass all the cables through the mesh loom.

-

Rout the cables and mesh loom through the loom splitter, using it to cover the joint between the three sections of mesh loom.

-

Add a zip tie to the mesh loom, just above the loom splitter, to secure it in place. See photo for reference.

-

-

-

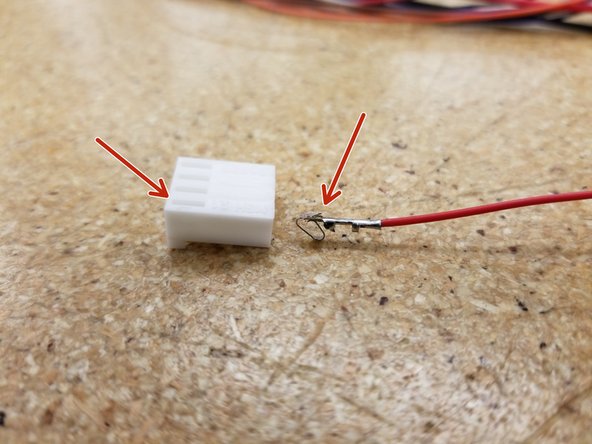

Insert the KK connectors as shown, making sure that the small tab on the metal wire crimp is aligned with the tab hole on the plastic connector.

-

Again, if inserted properly, you should hear and feel a satisfying click as the tab seats. Give the wire a gently tug to make sure it's seated properly.

-

Repeat for the remaining KK connectors, carefully following the wiring diagram from earlier.

-

-

-

Use your completed whip in your machine!

-

The PTFE tubing is shown not installed as your installation may vary depending on which machine the whip is installed.

-

Cancel: I did not complete this guide.

2 other people completed this guide.