-

-

Remove the white plastic springs. Stretching one side at a time to release the ball on the spring. Set aside.

-

-

-

Pull each ball joint, unsnapping the arm from the ball studs.

-

Save arms just in case you need to return to a stock configuration.

-

-

-

Snap all six new carbon fiber arms.

-

Install the six white plastic ball springs.

-

-

-

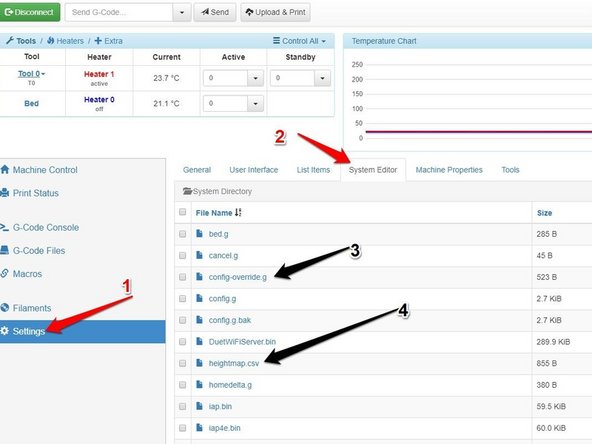

Connect to the printer and navigate to Settings>System Editor

-

Delete the following files:

-

config-override.g

-

heightmap.csv

-

-

-

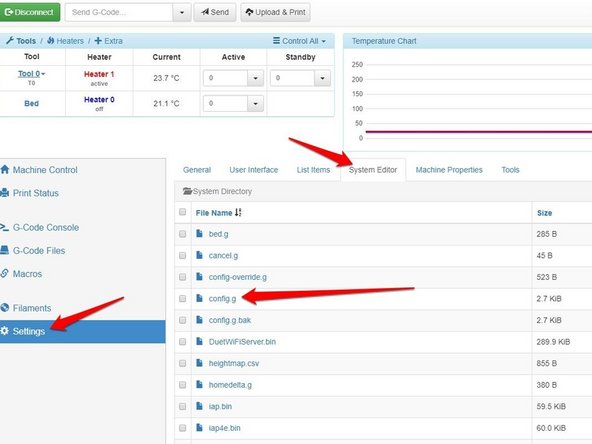

Settings>System Editor

-

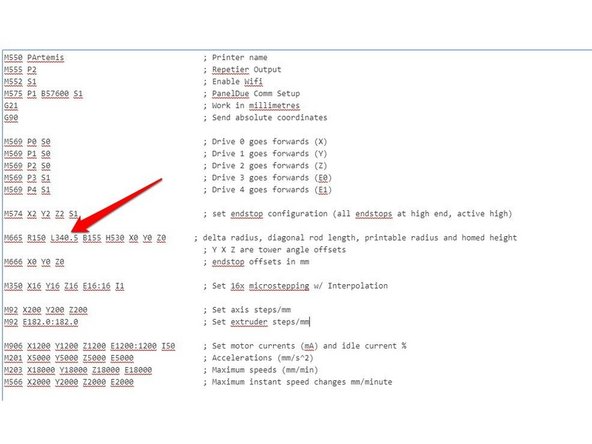

Edit config.g - locate line M665, usually about 10 or 12 lines down.

-

Artemis 300 set L to 340.5 (L340.5)

-

RostockMAX v3.2 AND v4 machines set L to 340.5 and H to 350.

-

If you do not change the H value, the machine will crash into the glass before being able to probe. The carbon fiber arms are longer than stock arms, shortening the max Z length.

-

The arm length value is a starting point. Although the arms are made in a precision jig, there may be variances and this value may need to be slightly adjusted if you are looking to print parts with specific size values. Adjusting and re-calibrating may be needed to tweak the final print size output.

-

-

-

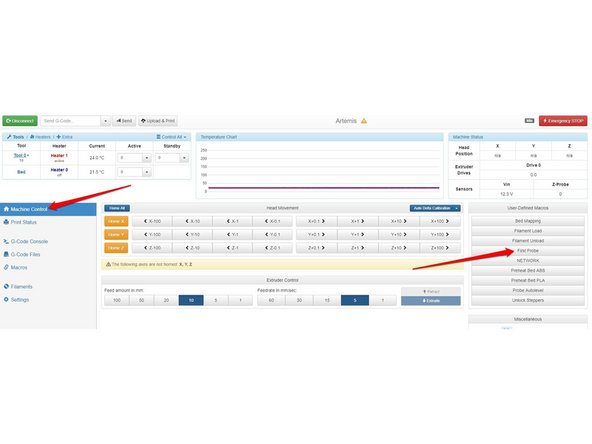

Save and reset, reboot, or power cycle the printer

-

Prepare for probing by clearing the nozzle and print bed as usual

-

Click the macro 'First Probe'

-

Wait for completion.

-

-

-

Remember DO NOT use the button labeled "Auto Delta Calibration" Instead we use the macros we wrote.

-

Remember NEVER use software auto leveling in any slicing software. Auto leveling and calibration is performed by the firmware on ALL SeeMeCNC 3D printers.

-

Remember when cleaning glass or changing a nozzle to use "Probe Autolevel" calibration macro.

-

The "Probe Autolevel" macro calibrate your printer using SeeMeCNC developed g-code.

-

Cancel: I did not complete this guide.

2 other people completed this guide.