-

-

Please follow the "Quick Start" Guide. Click this link to jump to SeeMeCNC Quick Start

-

If you purchased your printer before July 2019, please continue to Step 2.

-

-

-

If you purchased an RTP (ready to print) please skip this step.

-

CLICK HERE > Follow this guide to download and install the latest firmware

-

RostockMAX v4 DIY Kits now come with an SD card with current firmware downloaded onto the card. You can skip this step.

-

-

-

If you purchased a fully assembled RTP (ready to print) machine, please skip this step.

-

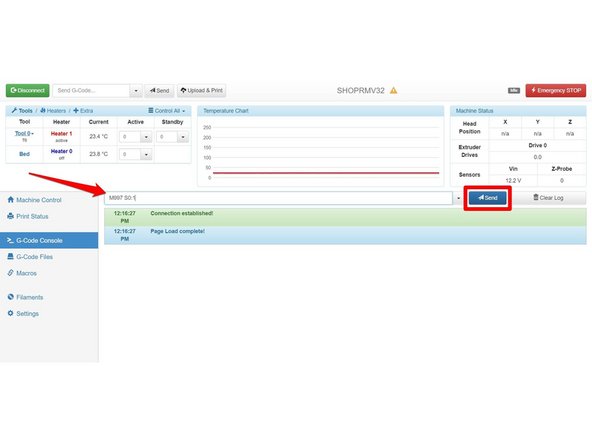

Go to the "G-Code Console" page.

-

In the text field, type in M997 S0:1 . This command manually triggers a firmware update to the latest version.

-

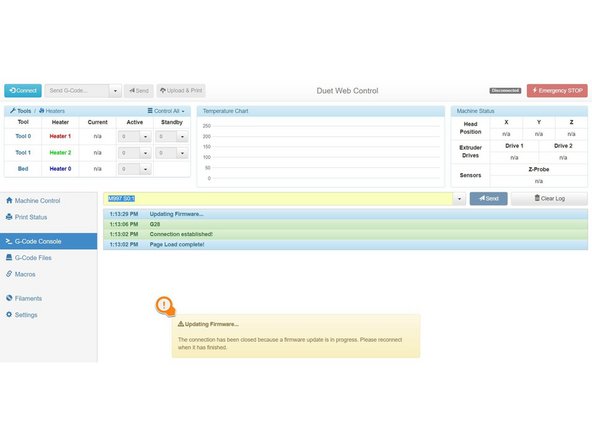

If done successfully, you should see an attention box telling you the connection has been terminated while updating the firmware.

-

Wait a minute or so, then reconnect to the printer using the blue "Connect" button at the top left of the window.

-

-

-

If you purchased a fully assembled RTP (ready to print) machine, please skip this step.

-

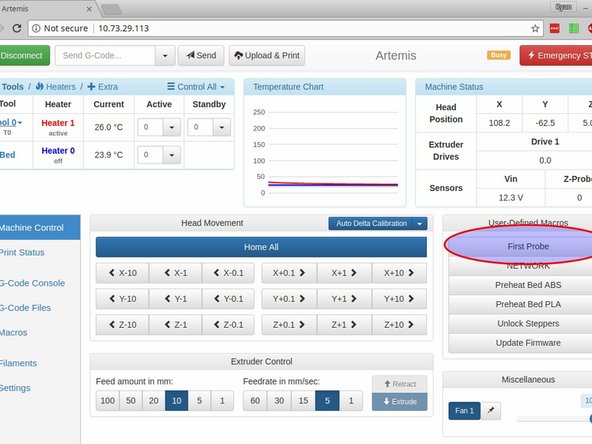

We have created a custom macro to assist with your first calibration. On the "Machine Control" tab, you can click "First Probe" under "User-Defined Macros" to do your first calibration.

-

The first probe macro will do a 10 point calibration (single tapping), then do a large bed map (double tapping), then a final 10 point calibration (double tapping). It will take about 5 minutes to run all the way through. Don't worry, future calibrations go much faster.

-

The first probe macro will automatically pre-heat the bed.

-

Run "G28" in the gcode console to home all of the axes. Test your calibration by putting a sheet of paper on the bed and running: "G0 Z0". Your nozzle should just touch and pinch the paper so it's hard to move. If it's too loose, run the following GCode: "G31 P100 X0 Y0 Z-0.1", then run "G32" to recalibrate, then "M500" to save your settings.

-

If it's too tight, you want to try "G31 P100 X0 Y0 Z-0.3", then run "G32". If it's still too tight, make the number after Z a larger negative number. If it's still too loose, make it a smaller negative number.

-

After your initial calibration, you can calibrate by clicking the "Auto Delta Calibration" button, or by sending "G32" in the gcode console.

-

You might see a line or two that says the Height Error Difference was above the maximum tolerance. Don't worry about them - if there's a real problem it will abort the calibration.

-