-

-

Open MatterControl and click the "Printers..." button and then click on the Add New Printer button.

-

You'll be presented with a Setup Wizard that will allow you to enter the Make & Model of the printer you're adding. In this case, you'll chose SeeMeCNC for the Make and Rostock MAX v3 for the model. Note that if you're using the SeeMeCNC branded version of MatterControl, SeeMeCNC will be the only Make available.

-

The next page of the Setup Wizard will ask to install a Communications Driver. If you installed one during the MatterControl install process, you don't need to install a driver here. For Mac & Linux users, no driver is required.

-

-

-

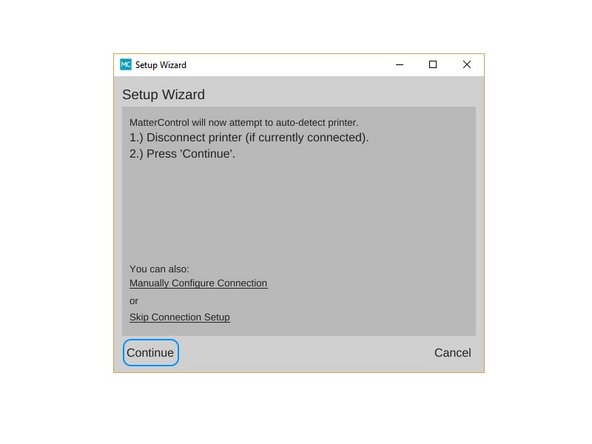

The next Setup Wizard page will instruct you to disconnect your printer to allow it to detect what port it's attached to.

-

Once the Setup Wizard has detect the port your printer is connected to, you can click the Connect button in order to complete the configuration process.

-

-

-

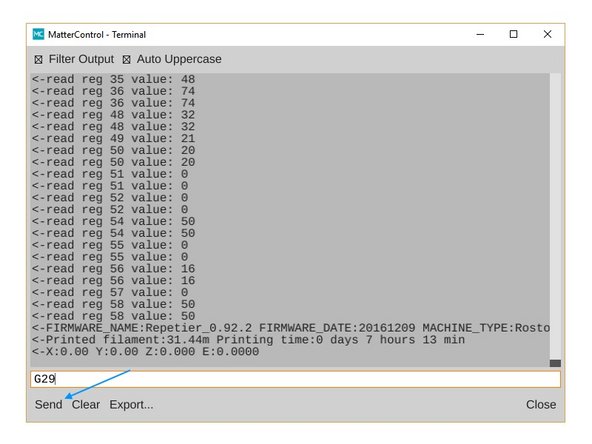

The next task is to perform the initial calibration of the printer. This is done by sending a "G29" command to the Rostock MAX v3.

-

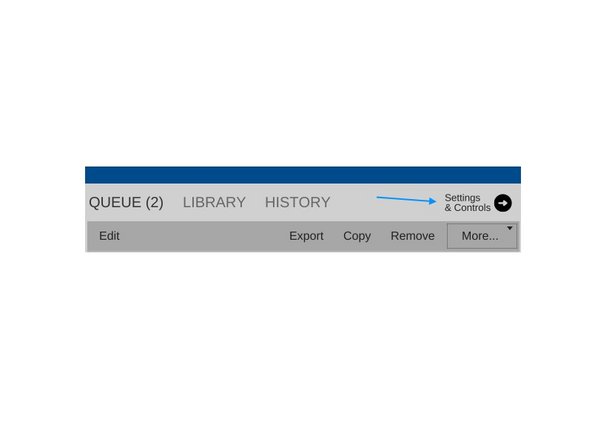

Click on the Settings & Controls button as indicated.

-

Click on the Options button and then click on the Show Terminal button. This will open up a serial terminal that you'll use to talk to your Rostock MAX v3.

-

-

-

Once the Serial Terminal window is open, type G29 into the input line as indicated and press Enter, or click the Send button.

-

Sending G29 starts off the built-in calibration process that is needed to get the Rostock MAX v3 to a state where a more accurate calibration can be performed.

-

-

-

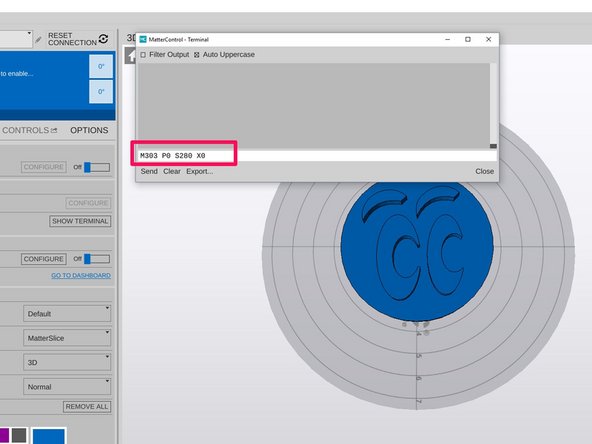

Next you need to PID Tune your hot end. This will ensure that the algorithm that controls the power to the heating element is working at optimal performance.

-

Send the following command via the terminal: M303 P0 S235 X0

-

After you have run the PID tune via MatterControl you should disconnect from MatterControl and then re-connect before performing any further operations.

-

Auto-Tuning is an iterative process, so run the routine again via the terminal, sending: M303 P0 S235 X0

-

Full explanation: M303 is the instruction to start the Autotune Process, P0 instructs it to perform the test for the hotend, S250 sets the temperature to run the test to, and X0 is the instruction to save the results to EEPROM.

-

If you plan to print high temperature materials you should run a PID Auto-Tune at a higher temperature at the target temp that you plan to be printing at.

-

-

-

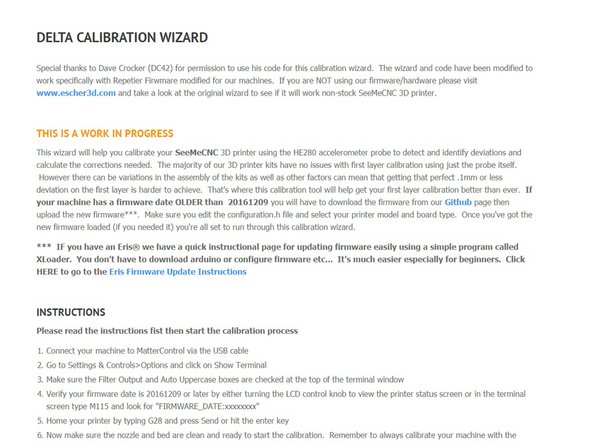

If your first layer is not as level as you wish you can run an advanced calibration. To do this, you'll need to open a web browser to SeeMeCNC's Delta Calibration Wizard. This web site will guide you through the remaining steps required to finish the calibration of your new Rostock MAX v3!

-